What do we do?

Electronics Assembly

With a commitment to excellence, we specialise in the assembly of surface mount and through-hole components using advanced Siplace machinery and expert hand assembly. Our process ensures precision and reliability, from initial assembly to final product testing. Driven by a robust sage MRP system, we efficiently manage materials to deliver high-quality products directly to you or your customers.

Surface Mount Technology

Surface Mount Technology uses automated production lines to paste and solder electronic components directly onto the surface of circuit boards. This technique has changed modern electronics assembly and it is easy to understand why.

Our Surface Mount Technology

We have four Siplace surface mount lines within our facility which are all standardised and provide excellent flexibility for your production scheduling needs.

The Process

Our Surface Mount process can be summarised as –

Solder Paste Print

↓

Component Placement

↓

PCBA Reflow

↓

Inspection – AOI / X-Ray / Stereo-scope

Automated Soldering Options

We invest in high quality automated soldering equipment which each provide us with unique capabilities. We use these, as well as traditional hand soldering, so we can work with a number of different boards.

Wave Soldering

Our state of the art Blundell CMS400 wave solder machines work at high speed passing components over a wave of molten solder to secure components to the board. Our machines are reliable and flexible and provide us with the capabilities to solder both surface mount and through-hole components.

Selective Soldering

Our selective soldering machines allow specific components to be soldered without exposing the entire assembly to heat. It is extremely flexible and is ideal for mixed technology boards.

Robotic Soldering

Our robotic soldering systems are programmed to achieve high levels of accuracy by applying molten metal to join components.

Hand Assembly

While we invest heavily in the newest technology, we also utilise the skills and technical proficiency of our experienced staff to assemble, solder and provide box build services to our clients.

Hand Assembly

Our Mascot Robotas equipment significantly enhances our hand-assembly capabilities by providing operators with guided assembly instructions, real-time visual inspection and improved process control. This technology helps ensure greater accuracy, consistency and overall product quality throughout the assembly process.

Box Build

We also offer box build assembly, sometimes referred to as full product assembly. This means that we can create a complete and ready to use product for our customers to use or sell. We ensure all of our box builds undergo stringent testing and are ready for our customers.

Hand Soldering

Our skilled technicians use soldering irons to achieve precision and unmatched quality. This is extremely useful for working on prototypes or boards with particular requirements.

Conformal Coating

At Stewart Technology, we provide high-quality conformal coating solutions that protect your electronic assemblies from moisture, contaminants, corrosion and extreme environments. Our advanced coating capabilities ensure long-term reliability for products used in demanding applications.

Design for Manufacture

Our engineering team at Stewart Technology partners with you from the earliest stage of product development to optimise your design for efficient and cost-effective manufacturing. Our detailed DFM analysis includes component selection, PCB layout guidance and assembly optimisation. By incorporating manufacturability into the design process we ensure your product is built right the first time and every time after.

Direct Dispatch

Stewart Technology streamlines your supply chain with our efficient direct dispatch. We can ship directly to you or to your customers, reducing time, handling and cost. With robust quality checks, secure packaging and flexible logistics coordination, we ensure your packages arrive exactly as intended.

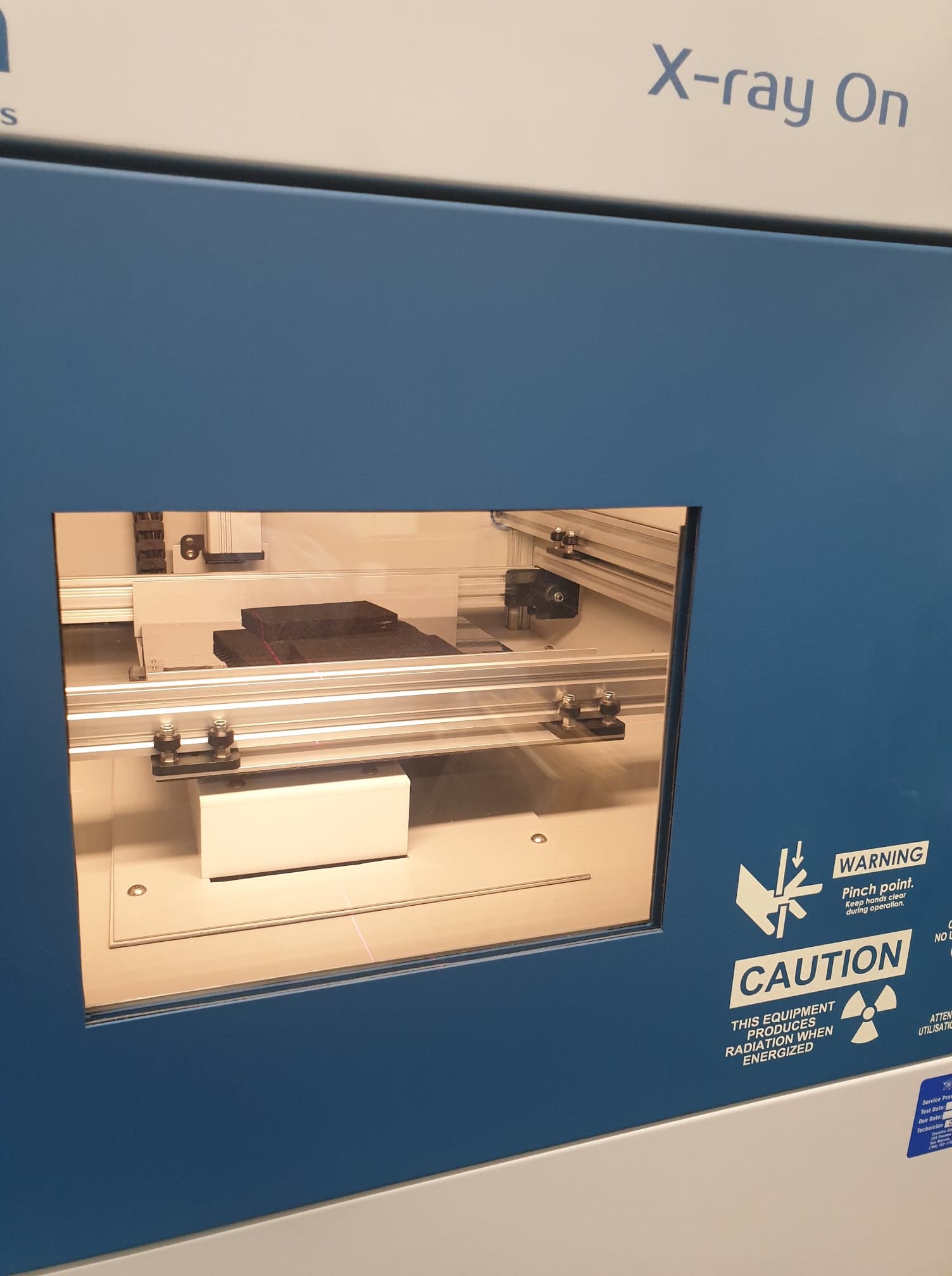

Inspection Capabilities

By combining AOI, X-ray and Mantis inspection, Stewart Technology delivers comprehensive quality assurance for all board types and complexity levels. Customers benefit from reduced defects, increased reliability and confidence that every product leaving our facility meets exacting standards.

Test

At Stewart Technology, thorough testing is an essential part of our commitment to quality and reliability. Every assembly undergoes rigorous electrical and functional testing to ensure it meets design specifications and performs flawlessly in the field. By combining advanced test equipment with experienced engineers, we provide customers with confidence, consistency and high-performing products every time.

Other Services we Provide

Technical Support

Modifications

Upgrades

Repairs

We offer repairs both in and out of warranty

Rework

Interested in Our Services?

If you are interested in how our Electronic Manufacturing Services could benefit your business please contact us!