Inspection Capabilities

At Stewart Technology , we understand that precision and reliability are critical in electronics manufacturing. Our comprehensive inspection capabilities ensure every assembly meets the highest standards of performance, safety and durability. By combining advanced technologies with skilled quality engineers we provide thorough verification of solder joints, component placements, internal connections and overall assembly integrity.

Our inspection processes are integrated at multiple stages of production from initial assembly to final system-level testing, reducing defects and giving our customers confidence in the products we deliver.

Automated Optical Inspection (AOI)

What is AOI?

Our Scanspection AOI systems use high-resolution cameras to capture detailed images of PCBs. Advanced software compares the images against the design specifications to detect defects such as missing or misaligned components, solder bridging and polarity errors. The system inspects boards during and after assembly, providing immediate feedback so errors can be corrected before further progression.

Benefits of AOI

Improves accuracy and consistency – AOI eliminates human error and ensures all boards are inspected to the same standard.

Reduces rework and scrap costs – By detecting defects early AOI prevents faults from becoming costly downstream issues.

Enhances production speed – AOI is faster than manual inspection, allowing projects to maintain quality without slowing output.

Continuous Improvement – AOI data helps to identify recurring issues in the assembly process, enabling targeted process optimisation.

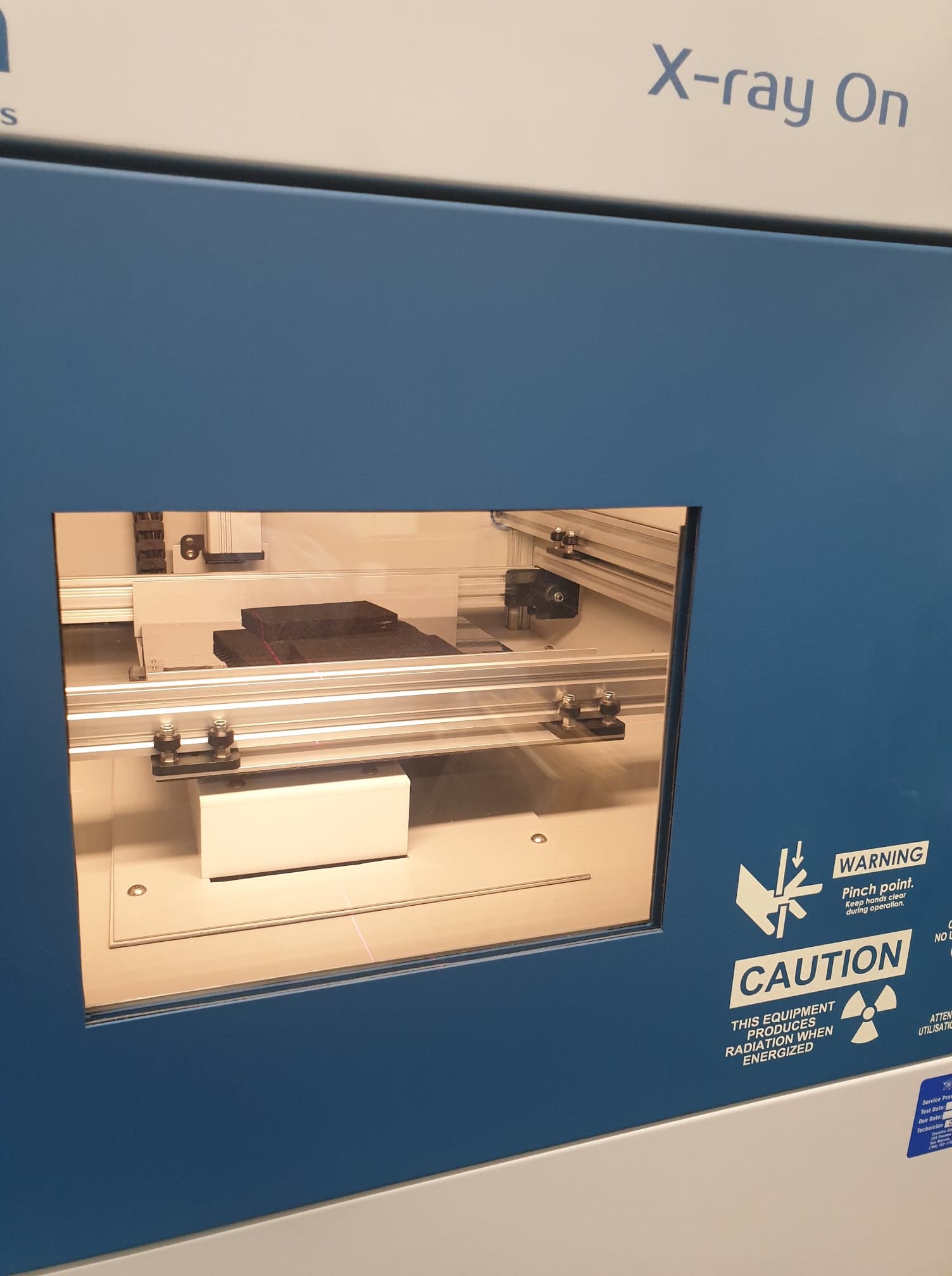

X-Ray Inspection

What is X-Ray Inspection?

Our TruView Prime X-ray system enables non-destructive inspection of hidden or internal features that optical systems can’t reach. X-rays pass through the PCB and the components, creating detailed images of internal structures such as BGA solder balls, bottom-terminated components, through-holes and multilayer board interconnections. This makes it possible to detect voids, insufficient solder, internal cracks, misalignments and hidden bridging.

Benefits of X-Ray Inspection

Reveals hidden defects – Ensures quality in BGAs, QFNs and other components where solder joints are not visible.

Improves long-term reliability – Has the capacity to identify micro-defects that may not cause immediate failure but can lead to faults over time.

Validates complex assemblies – Essential for PCBs where reliability is critical, such as high-density, multilayer or high value PCBs.

Confirms manufacturing quality – Ensures compliance with IPC standards and customer specific quality requirements.

Mantis High-Magnification Inspection

What is Mantis?

The mantis stereo-optical inspection system provides a high magnification, 3D visual view of assemblies. This enables operators to inspect very fine components, verify workmanship quality and examine detailed solder joints. Adjustable magnification and lighting allow for precise manual inspection of areas that automated systems may not fully capture.

Benefits of Mantis

Useful for prototypes and small batches – Allows technicians to examine early builds in detail, catching issues before scaling production.

Excellent inspection of fine details – Perfect for solder components, intricate solder joints and high-density PCB areas.

Useful for rework and repair – Gives technicians a magnified view needed for accurate correction of faults or component replacement.

Versatile and flexible – Useful across all stages of production – from initial builds to final checks.

Interested in Our Services?

If you are interested in how our Electronic Manufacturing Services could benefit your business please contact us!