Test

At Stewart Technology, quality and reliability are central to every product we build. Our comprehensive testing capabilities ensure that every assembly meets the highest performance standards before it reaches our customers. By combining skilled engineering expertise with advanced inspection and test equipment, we provide a robust verification process that supports industries where precision and dependability are essential.

Functional Testing

At Stewart Technology, functional testing is a core component of our quality assurance strategy. As we manufacture high-reliability electronics assemblies, we ensure that every product leaving our factory performs exactly as designed. This testing enables us to validate product performance, ensure customer satisfaction and maintain the high standards associated with the Stewart Technology brand.

Functional Testing Purpose

Confirm proper operation – ensure that each electronic unit performs its intended electrical, mechanical and software functions.

Detecting manufacturing defects early – identify assembly or process faults, such as incorrect components, soldering issues, firmware errors or wiring defects, before the products reach customers.

Ensure compliance with requirements – validate performance against customer specifications, internal standards and our ISO 9001 industry certifications.

Support zero-defect goals – reduce rework costs, minimise field returns and deliver products that reflect Stewart Technology’s values.

How we Do It

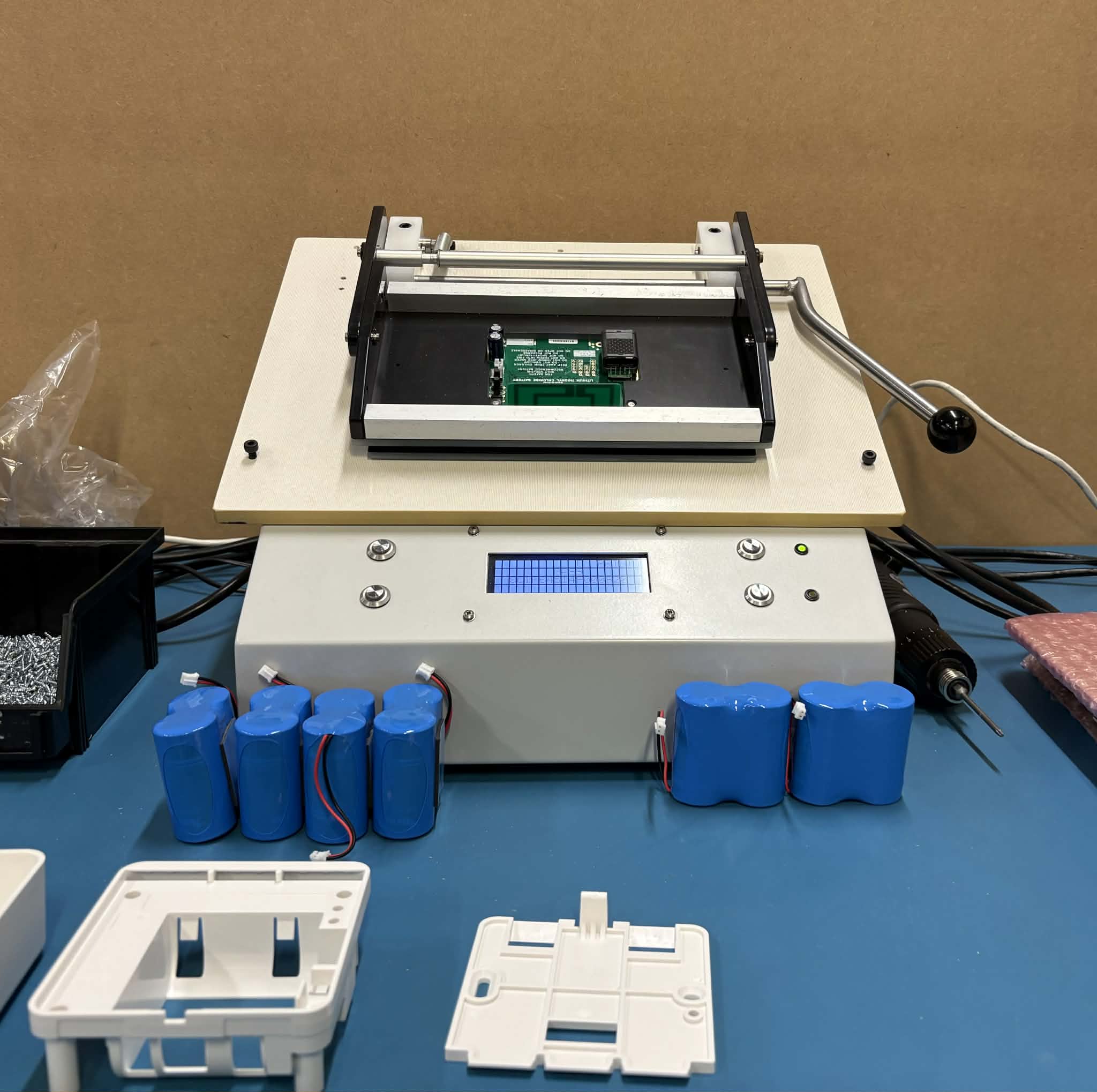

Custom Test Fixtures – Our skilled engineers design and manufacture custom test fixtures tailored to each product.

Advanced Test Instrumentation – Our functional test stations include programmable power supplies, signal generators, RF analysers and high-speed data communication interfaces.

Automated Test Software – We use automation to reduce operator variability, this includes step by step instructions for operators, automatic measurement, pass/fail evaluation and barcode scanning for traceability.

Device Interface Connections – We support a wide range of standard and custom interfaces including USB, RF antennas, Ethernet and special-purpose connectors based on customer design.

Types of Functional Tests Performed

We use our state of the art technology and engineer knowledge to create testing equipment which is suitable and specific to your product.

Typical tests performed include –

Power up / power verification tests

Programme configuration tests

Battery monitor tests

Temperature tests

A pass/fail evalutaion is then given for testing and conformal coating occurs after the testing process, for further protection.

Why Choose Stewart Technology for Testing?

End to End System Validation

We verify product functionality under real operating conditions to ensure every unit performs exactly as intended.

Deep Engineering Expertise

Our team has extensive experience within the industry and a strong understanding of testing, allowing us to handle even the most complex of functional tests.

Full Traceability

Every units test results are stored and available for audits or analysis. All tests are logged and linked to a serial number, allowing long-term tracking.

Interested in Our Services?

If you are interested in how our Electronic Manufacturing Services could benefit your business please contact us!